Blog

Comparision of Leak Detection Sensors

Types of Leak Detection Sensors: A Comprehensive Comparison

Discovering and addressing water and fluid leaks promptly is crucial for preventing damage and minimizing costs. Various Leak Detection Sensors are available, employing different methods to detect leaks. By comparing these sensors, you can make an informed decision based on your specific needs. Here are the main types of leak sensors:

- Direct Contact Leak Sensors: Also know as Spot probes or Point sensors. These leak sensors are designed to monitor specific locations with a higher perceived risk of leaks. They are ideal for areas such as laundry rooms or utility rooms, where leaks from appliances like washing machines, boilers, water heaters, or water softeners can occur. When water touches a probe it triggers an audible alarm or lights a flashing beacon.

- Water Leak Detection Cable or Rope: Water leak detection cables or ropes provide coverage for larger areas. They consist of a cable around which a pair of sensing wires are concentrically wrapped. When a conductive fluid comes into contact with the cable, it completes an electrical circuit, triggering an alarm. Please read this informative artice to learn more about our water detection cable.

- Flow Based Alarms Connected to a Ball Shut-Off Valve: These Water Leak Alarms consist of a water meter and a ball shut-off valve. These Leak Systems detect abnormal water flow rates, signaling an alarm and automatically closing the main water supply. The mechanical water meter typically contains a nutating disc that rotates through a cycle, dividing the metering chamber into sections of known volume. By counting the rotations of the disc, an accurate measurement of the water flow rate can be obtained. To obtain more detailed information on how our services assist clients in meeting WAT02 and WAT03 criteria, we invite you to read our article on BREEAM water detection.

How do CMR Electrical Direct Contact Leak Sensors Work?

By understanding the different types of leak sensors available, you can choose the most suitable option for your specific requirements. Proper leak detection ensures timely intervention and safeguards your property against water damage. In this article we are going to explore in more detail the different types of Direct Contact Leak Sensors. This will help you decide which one to choose that wlll be benefical to your specific requirements.

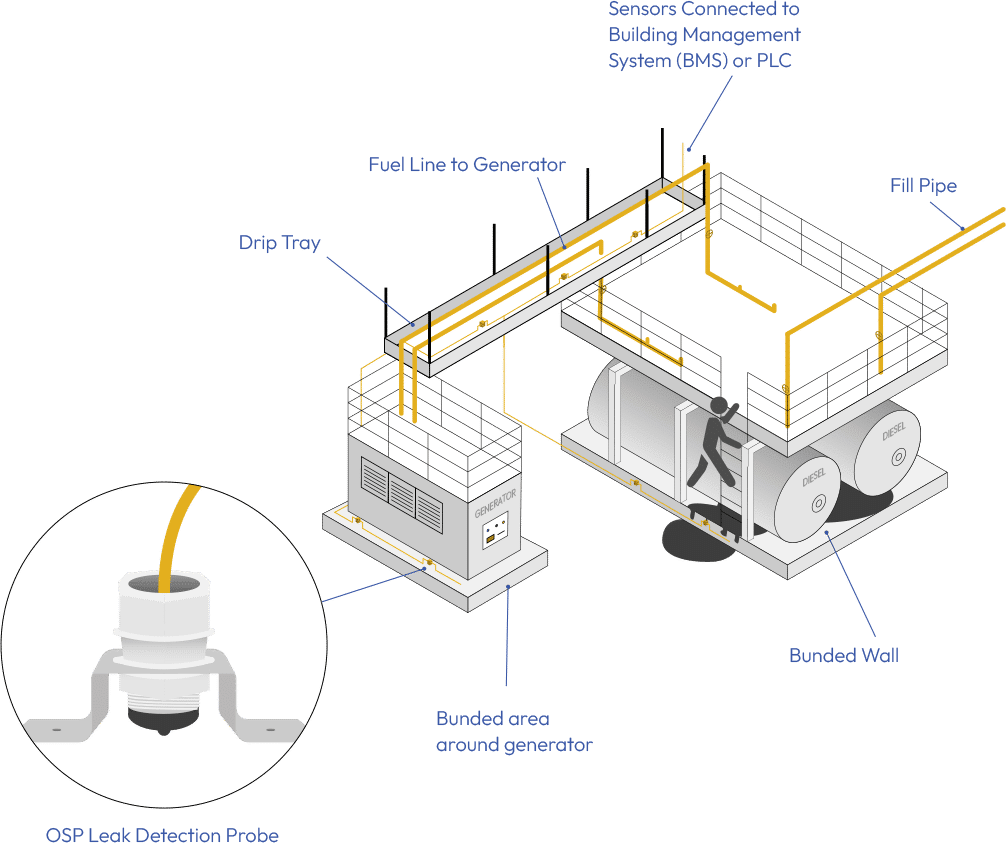

The above illustration demonstrates the installation of multiple OSP spot probes in a drip tray located beneath a Fuel Line to a Generator.

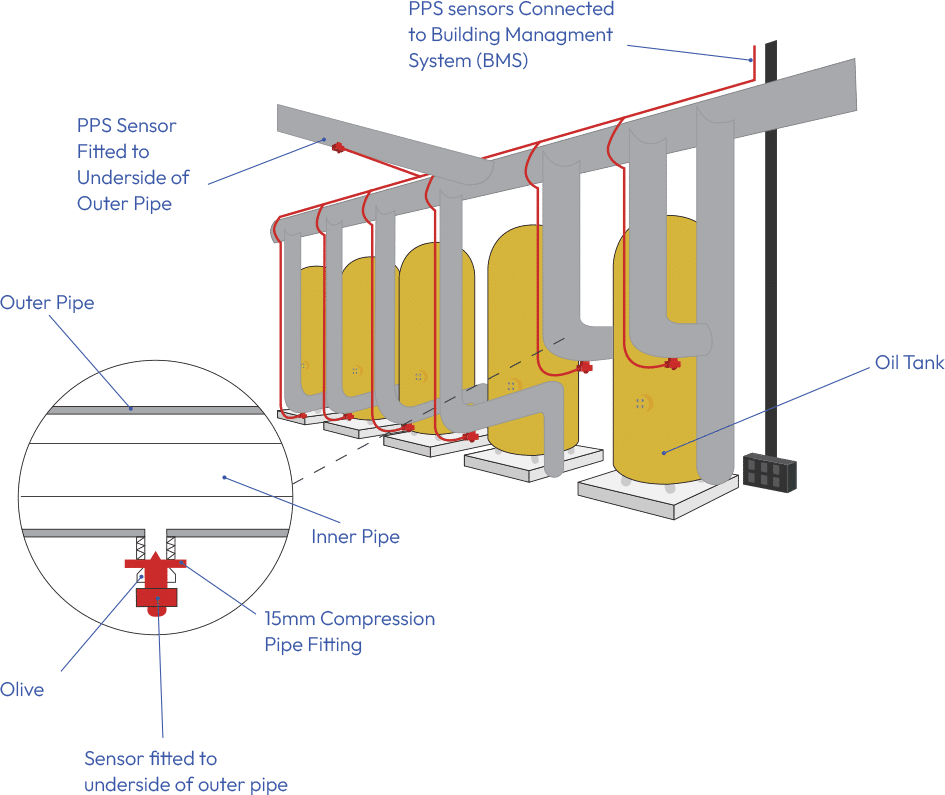

The above diagram illustrates the fitting of a PPS Sensor onto an outer pipe, specifically designed to detect leaks from the inner pipe.

At CMR Electrical we use Optical Sensors to detect the presence of any liquid. This can be a variety of conductive and non-conductive liquids regardless of viscosity, reflectivity, or colour.

Watch our YouTube clip below to see how our OSP Optical Sensors work when connected to our One to Four Zone Oil Leak Detection System – Type ODS4-3.

Summary of the features used in our Optical Sensors

- Uses no moving parts.

- Does not use conductivity to detect liquid.

- Infra-red LED and phototransistor which are optically coupled by the tip when the sensor is in air.

- When the sensing tip is immersed in liquid, the infra-red light escapes making the phototransistor output change state.

- Encased in Polysulfone to make it chemically resistant.

- Works for any liquid regardless of viscosity, reflectivity, or colour.

- Operating temperature -25°C to +80°C

Benefits of using CMR Electrical Optical Probes:

- Accurate, fast response, high reliability, long life

- Can be easily cleaned after contact with chemical/liquid to be re-used again

- Ideal for applications where space is limited

- Low cost

- Easy to install

- Compatible with wide range of fluids & chemicals

- Easy to interface with customer equipment

Comprehensive coverage for all leak detection possibilities

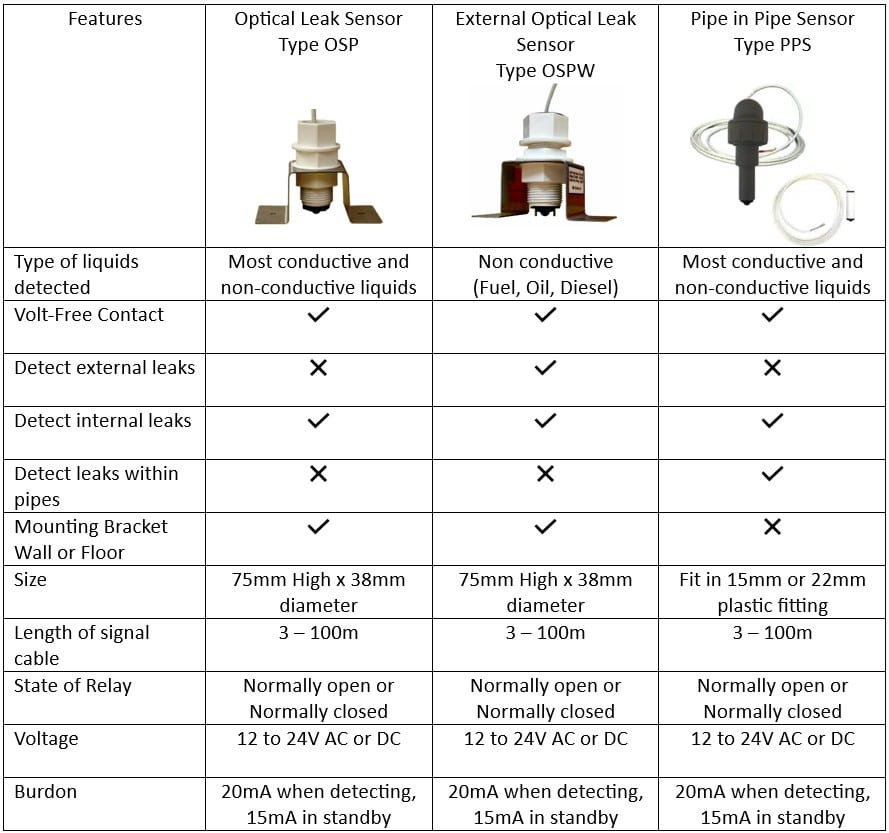

The table below shows a comparison of our different sensors:

For any further information on our water and oil leak products and how we can help you meet your specific requirements, get in touch with us at CMR Electrical or phone 01825 733600.